Airbus is taking a decisive step towards a new era in aeronautical manufacturing. Far from grandiose headlines, the change is profound: critical titanium structural components are no longer machined from solid blocks but are “grown” layer by layer from a metal wire. The technology making this possible is called wire-Directed Energy Deposition (w-DED) and has already begun to be integrated into production for the A350.

This move marks a turning point in costs, industrial timelines, and design philosophy, with direct implications for manufacturers, suppliers, and airlines.

What is w-DED and Why is it a Game-Changer?

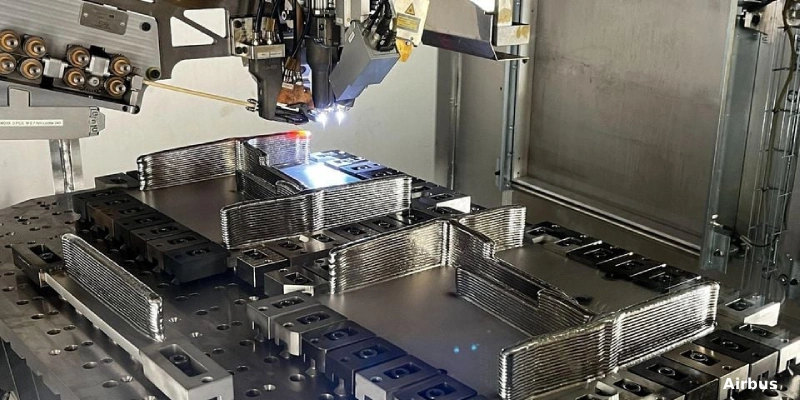

Wire-Directed Energy Deposition is an additive manufacturing technique that uses titanium in wire form, continuously fed into a concentrated energy system—laser, plasma, electric arc, or electron beam—which melts and deposits it with millimeter precision.

A multi-axis robotic arm, guided by a digital model, builds the component layer by layer until a near-net-shape part is obtained: a geometry very close to the final one, requiring only minimal subsequent machining.

Unlike traditional powder-bed-based metal 3D printing, historically limited to small parts (typically under 60 centimeters), w-DED enables the fabrication of structural components up to seven meters long. This scale is what, for the first time, opens the door to its industrial use in large commercial aircraft.

From Grams to Kilograms per Hour: The Industrial Leap

One of the major brakes on metal 3D printing in aviation has been productivity. Powder-bed systems operate at rates of hundreds of grams per hour, suitable for fittings or secondary parts, but unfeasible for primary structures.

With w-DED, Airbus increases that figure to several kilograms per hour, an order of magnitude higher that allows for series production and not just niche applications. This shift is key to justifying the industrialization of the process in commercial programs.

→ Airbus Takes a Key Step Towards Circular Economy by Recycling A380 Components for A320neo

Titanium: A Critical Material, Critical Waste

The focus on titanium is no coincidence. It is an essential material in modern aeronautics due to its high mechanical strength, low weight, and compatibility with composite structures, especially in terms of corrosion and thermal expansion coefficients.

But it is also an expensive material. In traditional forging and machining processes, the key indicator is the buy-to-fly ratio: the amount of material purchased versus what actually flies on the aircraft. For forged titanium components, between 80% and 95% of the initial material ends up as chips, which must be recycled at high energy and economic cost.

Additive manufacturing with w-DED drastically reduces this waste from the outset, by building only the necessary material. The result is a much more efficient use of titanium, with a direct impact on costs and industrial sustainability.

Industrial Agility: Weeks Instead of Years

Another structural change lies in timelines. Traditional forging requires complex tooling, with high initial investments and lead times of up to two years for its development.

In contrast, with w-DED, the geometry of the part depends on software, not a physical mold. This reduces the launch time to just a few weeks, a critical advantage during the initial phases of a program’s development, when designs are still being adjusted and optimized.

For Airbus, this agility is especially valuable in building the first development aircraft, where every iteration counts and time is a strategic factor.

The A350 as a Real Test Bed

Far from remaining in the lab, Airbus has already taken the step to production. The company has begun the series integration of the largest w-DED parts in the A350 cargo door surround area.

These parts, designed by Airbus, were:

- 3D printed by a qualified supplier using plasma w-DED

- Inspected by Testia Bremen using ultrasound

- Subsequently machined and installed on Airbus production lines

From a functional and geometric standpoint, they are identical to the traditional forged parts they replace, but already offer immediate cost savings in a real operational environment.

The next objective is to gradually progress towards more critical applications and extend the technology to other programs and aircraft areas, including wings and landing gear in the long term.

“Designed for DED”: When Design Truly Changes

Perhaps the most transformative aspect is not the process, but the mindset. Airbus already speaks of “designed for DED.”

Until now, many complex parts had to be divided into multiple components, later joined using fasteners or welds. With w-DED, engineers can design a single, optimized part, printed in one go.

This enables:

- Reducing the number of components

- Simplifying the supply chain

- Decreasing assembly labor

- Shortening industrial cycles

Overall, it is a key lever to unlock the potential of the next generation of natively 3D-designed aircraft.

A Technological Race Underway

Airbus and its partners are already immersed in a race to accumulate industrial experience with w-DED for critical parts. Multiple energy sources—plasma, arc, laser, and electron beam—are being evaluated, as well as “Make or Buy” strategies, combining in-house production and external suppliers.

The approach is corporate: as it is a group-level initiative, the developed technologies will be standardized and can be applied across the entire company, consolidating w-DED as an industrial pillar and not just a one-off solution.

What Airbus is doing with titanium 3D printing is quietly redefining how aircraft are manufactured: less waste, more agility, smarter designs, and more controlled costs.

Related Topics

FAA and EASA Grant Initial Certification to Boeing 777-9 Simulators, Enabling Pre-Training Phase for Pilots

Vietnamese Airlines Sign Agreements for 90 Boeing Aircraft

Air Astana Finalizes Largest Order in Its History: Up to 15 Boeing 787 Jets

Boeing to Inaugurate Fourth 737 MAX Production Line in Everett by Mid-Year

Un apasionado por la aviación, Fundador y CEO de Aviación al Día.